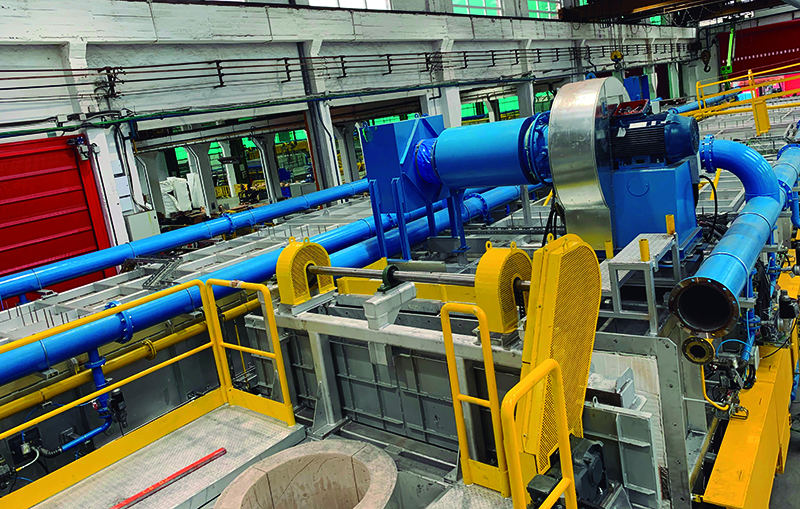

SIDENOR Basauri and GHI are setting up two advanced heat treatment lines for steel bars. These lines, 130 meters long, are built for high flexibility and incorporate 4.0 connectivity.

Strategic Technological Advancement

These first lines from a new generation of furnaces show major technological improvements. They also mark the start of using lean manufacturing principles in production, raising industry standards in furnace design and functionality.

SIDENOR worked closely with GHI to design the 100-meter long furnaces. Each comes with entry and exit tables and cooling systems, adding another 30 meters to each line. This setup enhances the treatment capabilities significantly.

Jose Berasategui, General Manager at GHI, highlights the operational flexibility these furnaces offer. They quickly adjust settings for treatment durations and temperatures, which boosts production efficiency.

Enhanced Capabilities and Safety Features

The furnaces expand the range of bar qualities SIDENOR can treat. They handle processes like annealing and tempering across varying durations from six to 28 hours.

These furnaces treat steel bar packages weighing 5 to 10 tons and measuring 3 to 12 meters in length and 20 to 120 millimeters in diameter. They automate the feeding and alignment of bars, which enhances safety for operators.

SIDENOR expects these lines to be fully operational by April 2020. The assembly of the first line is complete, and the second line is currently undergoing tests at GHI’s workshop.

For further insights, read the full article in Estrategia Empresarial.