At GHI Smart Furnaces, we are continuously pushing the boundaries of innovation to improve energy efficiency in industrial processes. Our latest project, developed in collaboration with Befesa Aluminio, Nervacero, Bs-tech Rolling Mill, and Tecnalia Technology Center, focuses on advancing technologies that enhance the efficiency of industrial furnaces.

Project Overview: FACOEE

The FACOEE project is a significant step towards sustainable and competitive manufacturing. It targets two key areas:

- Recovery of Secondary Aluminum in Rotary Furnaces:

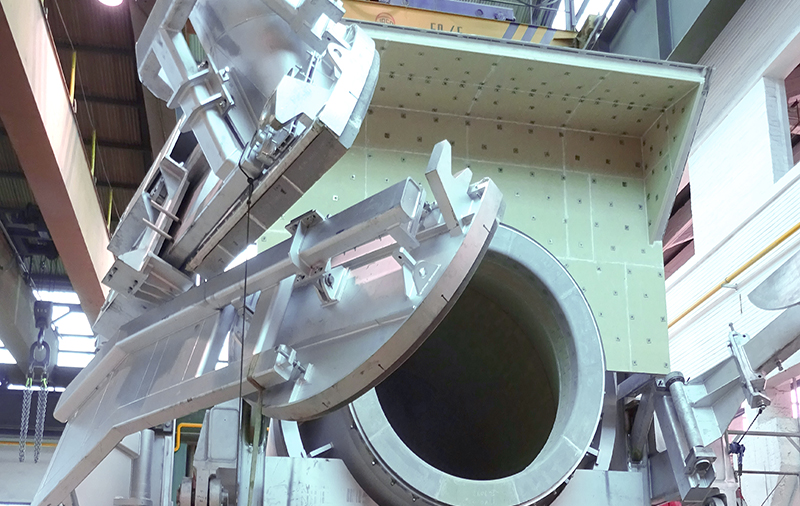

- Multi-Door System: This innovative system reduces temperature loss, prevents re-dipping, and allows for greater load utilization, thereby decreasing casting time.

- Regenerative Burners: These burners minimize metal oxidation, enhancing the quality and efficiency of the melting process.

- Reheating of Steel Billets in Walking Beam Furnaces:

- This component of the project aims to improve the reheating process, making it more energy-efficient and cost-effective.

Collaboration and Innovation

This project is a testament to the power of collaboration. By working with industry leaders like Befesa Aluminio, Nervacero, and Bs-tech Rolling Mill, and leveraging the technological expertise of Tecnalia, we are driving forward groundbreaking advancements in furnace technology.

Financial Support

The FACOEE project has been co-financed by the SPRI, Business Development Agency of the Basque Government, highlighting the importance and potential impact of our innovative efforts.