We have developed an original alternative for the hot rolling process of aluminium slabs, providing a more competitive, productive, and sustainable solution to companies in the sector.

Integral Solution

Until its implementation, there was only one plant of this type in the world, located in the US, which showcases our capacity for offering cutting-edge technology to our customers.

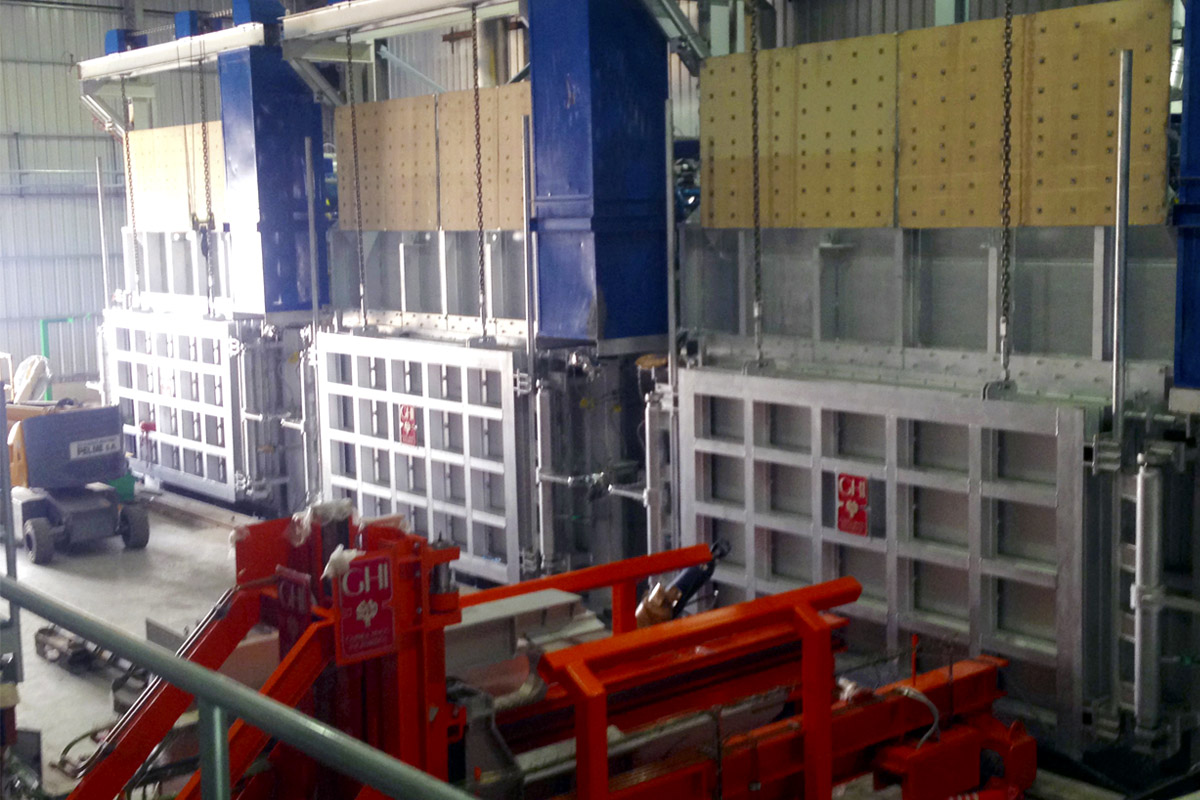

It is a modular installation comprising three chamber furnaces where the slabs to be laminated are heated, as well as a series of transfer machines that automatically introduce, extract, and transfer the heated slabs to the rolling mill.

Chamber furnaces, unlike traditional semi-continuous systems, are intermittent and have a horizontal chamber, which allows the treatment of small batches of slabs with different sizes and different alloys, and subject them to different heat treatment cycles.

Advantages

- Flexibility in terms of slabs sizes and treated batches

- Very short heating times thanks to the use of forced recirculation ventilators

- High homogenization in the heating speed of the slabs

- Better control of the production process thanks to the sensorization and technology 4.0

- Low energy consumption

- Reduction of gas emissions into the atmosphere