Almexa has awarded GHI Smart Furnaces the contract to supply equipment for its new casthouse in Veracruz. Set to be the most advanced and efficient in the Americas, the casthouse is scheduled to open in the second half of 2021. The key process equipment, provided by GHI Smart Furnaces, underscores GHI’s reputation as a world leader in the furnaces industry. This plant will feature cutting-edge aluminum processing equipment designed to support a circular economy.

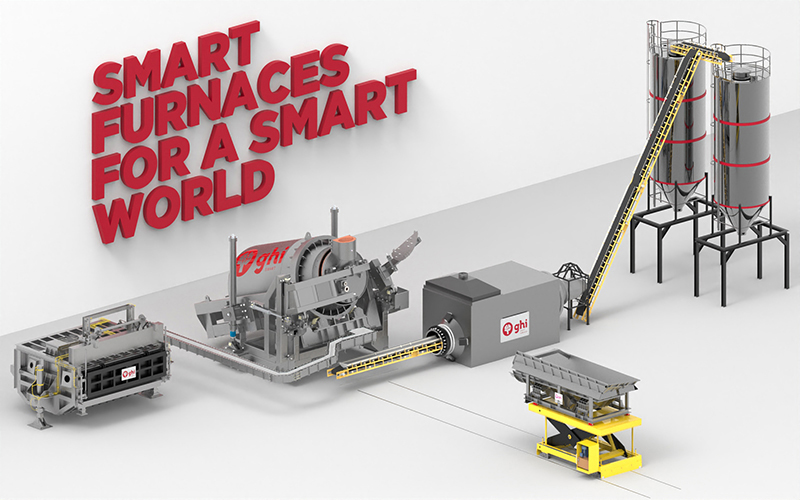

With a production capacity exceeding 90,000 tons per year, the plant will house the largest Tilting Rotary Furnace in the Americas, with a capacity of 65 tons. This furnace, one of only four in the world, is supplied by GHI and is specifically designed for aluminum recovery.

Additionally, the plant will include a salt slag cooling system to enhance metal recovery while minimizing environmental impact. A high-efficiency melting and holding furnace, with a capacity of 50 tons and equipped with regenerative burners, will also be installed.

The new casthouse aims to be a global benchmark for canstock production. It is meticulously designed to produce high-quality aluminum through an environmentally friendly process with full automation and smartization. The key equipment is fully sensorized, and the collected data is analyzed using Big Data and Artificial Intelligence solutions via the Beyond Alea platform to improve productivity and control of the Smart Plant.

The Tilting Rotary Furnace will serve as the main melting equipment, transferring the resulting aluminum to a new melting and holding furnace. Here, additional melting capacity will be installed, and the alloy will be adjusted before being transferred to the vertical casting machine.