Auxiliary Equipment for

Aluminium Recycling Plants

GHI Smart Furnaces is a leading provider of auxiliary equipment for aluminium furnace recycling plants. Our smart and efficient equipment are designed to optimize production processes, enhance yields, and ensure the highest safety standards.

Autonomous Skimming Machine

We offer an Autonomous Skimming Machine that is designed to enhance the quality and efficiency of aluminium recycling processes. This machine operates by effectively removing unwanted dross from molten aluminium, thereby ensuring clean and consistent metal quality.

The system is versatile and can operate in semi-automatic or fully automatic modes to meet the specific needs of each recycling plant. It uses a combination of sensors and robotics to remove dross from molten aluminium. The use of digital image processing cameras allows the automation of the skimming process.

- Safety

The machine operates autonomously, eliminating the need for an operator. This ensures the safety of the operators by keeping them away from the danger area in front of the furnace.

- Quality Assurance

The machine ensures clean metal for downstream processes, optimising performance in downstream extrusion and casting processes. The use of digital image processing cameras allows the automation of the skimming process, improving the efficiency of the process.

- Cost Efficiency

The efficient operation of the skimming machine minimises downtime and associated maintenance costs, reducing damage to the furnace. The autonomous operation of the machine also results in shorter door open times, reducing furnace cycle time and saving energy. Furthermore, it eliminates refractory damage and the downtime for refractory repairs.

Smart Salt Slag Cooler

The GHI Smart Salt Slag Cooler is an innovative solution designed to enhance the efficiency and safety of aluminium recycling plants. This equipment significantly reduces the plant space and personnel required, creating a cleaner, dust-free environment and minimising aluminium loss. It also decreases the number of slag bins and their maintenance by over 90%, reducing labour for slag bin handling and truck loading. These improvements contribute to a quieter and safer work environment with fewer vehicle movements. Furthermore, the system reduces fumes emission, contributing to a healthier work environment.

- Efficient Aluminium Recovery

The Smart Salt Slag Cooler maximises aluminium recovery from the salt slag produced by the tilting rotary furnace. This system cools the salt slag quickly, preventing aluminium oxidation. The salt slag is poured into a dedicated conveyor and introduced into the trommel of the cooling system, ensuring that it never gets in direct contact with the cooling water.

- Space and Energy Efficiency

The Smart Salt Slag Cooler requires significantly less space for cooling compared to traditional basket systems. It is designed to maximise metal yield from aluminium while minimising energy consumption.

- Environmentally Friendly

The GHI Smart Furnaces equipment provides greater energy efficiency and lower CO2 emissions per tonne produced, making the Smart Salt Slag Cooler an environmentally friendly choice for aluminium recycling plants. After the cooling cycle is completed, the dust and fines are transported to storage silos for further processing in salt recovery plants while coarse aluminium pieces are sent back to the melting furnace.

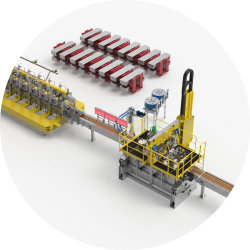

Sow Casting Lines

GHI Smart Furnaces presents our meticulously engineered sow casting lines. These lines are designed to produce solid metal blocks with unparalleled precision, eliminating manual handling and thereby minimising errors. The result is a highly efficient process that optimises productivity.

- Automated Sow Casting

Our sow casting lines are fully automated, eliminating the need for manual intervention. This reduces human error and improves consistency. We have incorporated an automatic sow mould pre-drying and demoulding system into the process.

- High-Precision Sow Production

We ensure consistent sow geometry and exceptional dimensional accuracy through precise control of the casting parameters.

- Efficient and Customisable Production

Our sow casting lines utilize a series of molds to cast multiple sows simultaneously. The mould number can be tailored to customer requests, and the moulds are strategically positioned on a conveyor belt. The capacity of this conveyor belt can be adjusted according to customer requirements, making our sow casting lines highly efficient and capable of producing sows with a high degree of precision.

- Additional Options

We offer additional options such as an automatic skimming robot, an automatic printing system, and an automatic sow stack and buffer conveyor belt.

Autonomous Charging Machine

At GHI, we have developed different types of Autonomous Charging Machines that automate the charging process of aluminium furnaces. This innovative technology utilizes advanced sensors and robotics to precisely transfer metal charging to the furnace, minimizing charging time and reducing the risk of furnace damage.

- Highly precise and controlled metal charging

The Autonomous Charging Machine ensures consistent and repeatable charging, maximizing furnace utilization. It includes the monitoring of each load's weight for precise control and process improvement, all managed through our platform, BeyondAlea by GHI Smart Furnaces.

- Reduced charging time

The automated process significantly accelerates charging, allowing for quicker furnace cycles, decreasing heat loss, and improving productivity.

- Minimized furnace damage

The gentle and controlled transfer of metal protects the furnace refractory lining, extending its lifespan and reducing maintenance costs.

- Enhanced safety

The autonomous operation eliminates the risk of operator injuries associated with manual charging.

Smart Cooling Chamber

The GHI Smart Cooling Chamber is an advanced equipment designed for aluminium plants, suitable for both billets or coil. This system is used for the controlled or non-controlled cooling of previously treated parts, serving as an active part of the treatment or to reduce the cycle time.

- Efficient Cooling System

Applies a controlled cooling rate by forced convection with air or water to the aluminium billets and coils after hot treatment. The cooling rate, contingent on the alloy, impacts the properties of the billets during extrusion.

- Reduced Process Time

Engineered to decrease the coil treatment process time, thereby enhancing the overall efficiency of the aluminium recycling plant.

- Versatility

Capable of both controlled and non-controlled cooling of previously treated parts. Can serve as an active part of the treatment or be used to reduce the cycle time.

- Smart Operation

Equipped with a series of roof fans that blow air across the load. Adjustable flow rate cold air intakes are strategically located around the fan housing area, enabling the regulation of cold air volume based on the required cooling speed. Can be fitted with a water-cooled cooling system and is constructed from stainless steel in such instances.

Transport Ladles

We offer specialized Transport Ladles designed for the safe and efficient transportation of molten aluminum throughout the recycling process. These robust ladles, designed specifically for road transportation, ensure the integrity of the liquid metal, providing an optimized solution for aluminium transport.

- Enhanced Safety and Reliability

Our ladles are constructed from high-quality materials and incorporate safety features to minimize the risk of spills or leaks. They are built under safety standards, with pressure and welding tests, complying with international road transport regulations, ensuring a secure transport environment for the molten aluminum.

- Optimized Heat Retention

The ladles are designed to minimize heat loss, ensuring that the molten aluminium maintains its temperature throughout the transportation process. They feature insulating and refractory coating that guarantee maximum thermal insulation.

- Reduced Downtime

The robust design of the ladles minimizes maintenance requirements and ensures extended service life. This results in reduced downtime, optimizing the overall efficiency of the recycling process.

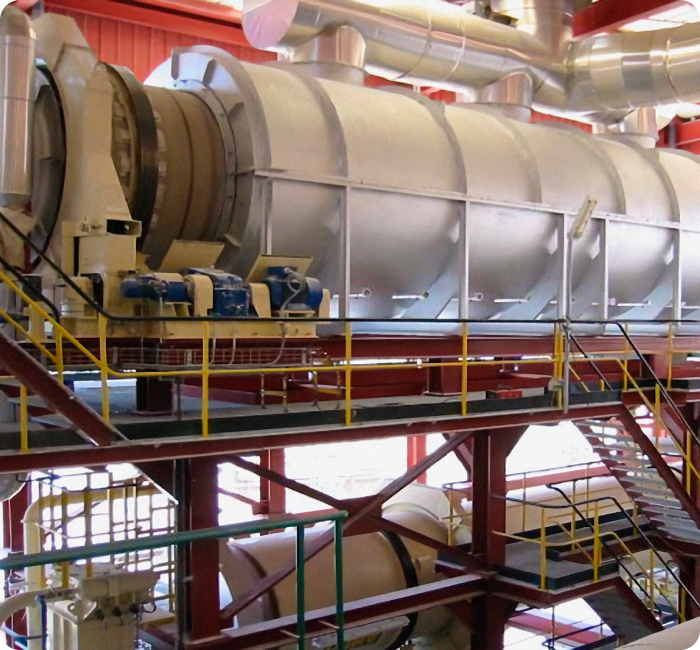

Decoating System

The GHI Smart Furnaces’ Decoating System is a cutting-edge solution designed to enhance the scrap recovery process in aluminium recycling plants. This system is engineered to handle can scrap of varying thickness, from 0.5 mm up to 200 mm.

- Higher Metal Yield

The Decoating System improves the scrap recovery process, resulting in a higher yield.

- Energy Efficiency

The system’s operation leads to lower energy consumption during the melting process, due to the combustion of organic components in the feedstock for the process itself and metal preheating.

- Effective Drying Process

The load is heated up to temperatures between 300°C and 350°C, effectively removing water and oil. This process is crucial to ensure the complete removal of moisture, even after a previous spin drying process.

- Efficient Decoating Process

The load is heated up to 500°C – 550°C, effectively eliminating VOC content.

- Environmentally Friendly

The Decoating System lowers fumes emission, making it a more environmentally friendly choice.

Cutting Saws

At GHI Smart Furnaces, we offer high-precision cutting saws that guarantee accurate and efficient cutting of aluminium billets to the desired length. Our cutting saws are designed to minimise waste and ensure consistent dimensions, enhancing the overall efficiency of your production process.

- Precision Cutting

Our cutting saws are engineered to cut aluminium billets with high precision, ensuring consistent dimensions and minimising waste.

- Versatile Integration

Our cutting saws can be seamlessly integrated with various automation systems, including weighing systems, ink marking systems, and stacking devices, to optimise billet handling and processing.

- Efficient Operation

Designed for fast and efficient cutting, our saws help reduce production time and labor.

- Customisable Blade Options

Depending on your needs and the size of the products, our cutting saws can be equipped with either circular or band blades.

- Chip Management System

For efficient management of cutting chips, our cutting saws come with a chips suction system and compacting press.

Ingot Casting Machine

Our innovative Ingot Casting Machines produce high-quality aluminum ingots with minimal waste. The molten metal from the furnace is distributed evenly into each mold, and the molds are then cooled and demolded using a knock-off system.

- High-quality ingots

The ingot casting machines produce ingots with consistent dimensions, low surface defects.

- Minimal waste

The efficient and reliable casting process minimizes ingots rejects, reducing the environmental impact of aluminium remelting.

- Automated process

The fully automatic process including the furnace tilting control eliminates the need for manual intervention, reducing human error and improving consistency.

Aluminium Scrap Sorting Equipment

The GHI Smart Furnaces’ Aluminium Scrap Sorting Equipment is a vital component in aluminium recycling plants. It is designed to separate various types of aluminium scrap based on their composition, size, and purity. This ensures the right type of aluminium scrap is used for each application, enhancing the quality and efficiency of the melting process.

- Cost-Effectiveness

The Aluminium Scrap Sorting Equipment is designed to achieve high levels of accuracy with error rates of less than 1%. This ensures that only the highest quality aluminium scrap is used in the melting process, leading to significant cost savings in the long run.

- Environmental Impact

The Aluminium Scrap Sorting Equipment can process large volumes of scrap quickly and efficiently. This reduces the time and labour required for the sorting process, leading to reduced waste and lower emissions.

- Customizability

The Aluminium Scrap Sorting Equipment can be configured to meet the specific needs of each recycling plant. This allows plants to optimize their sorting process for maximum efficiency.

Aluminium Billet Vertical Casting Machine

Our Aluminium Billet Vertical Casting Machine, employing direct chill casting technologies, is a game-changer in the production of high-quality aluminium billets. This vertical casting method ensures uniform cross-sections and reduces billet distortion, thereby promoting efficient subsequent extrusion processes and optimized material properties.

- Uniform Cross-Sections through Vertical Casting

The vertical casting process eliminates the upward flow of molten metal, resulting in billets with consistent cross-sections and reduced distortion. This process uses a cooled mould that is positioned vertically, ensuring uniformity and precision.

- Superior Billet Quality

Our vertical casting method minimizes oxidation and inclusions, leading to billets with superior mechanical properties and reduced defects. This is achieved through direct chill casting, which produces ingots initially by containing the liquid metal in a cooled mould and then by direct cooling of the casting.

- Efficient Subsequent Extrusion Processes

The uniform billet geometry produced by our machine promotes efficient extrusion, resulting in high-quality aluminium profiles with consistent dimensions and reduced material waste. The cooling medium is water, used both for the mould cooling (primary cooling) and the direct or secondary cooling.

Fume Treatment Equipment System

At GHI Smart Furnaces, we offer state-of-the-art fume treatment solutions designed to safeguard the health and well-being of employees. Our autonomous fume treatment systems effectively capture and filter harmful by-products from the aluminium recycling process, ensuring a safe and healthy working environment.

This is achieved by integrating filter control into the management logic of the entire fusion plant, optimizing system performance and enabling the use of improvement tools from our Beyond 4.0 platform.

- Efficient Fume Capture and Filtration

Our fume treatment equipment captures and eliminates harmful by-products, including Hydrogen Fluoride (HF), Hydrogen Chloride (HCl), Dioxins (PCDD/PCDF), Sulphur Oxide (SO2), and solid particles.

- High-Efficiency Filtration Systems

Our filtration systems are automatic, with dosage and pneumatic transport of additives (lime and active carbon) to reduce harmful emissions. These systems have proven to operate for many years in the harshest environments with little to no upkeep.

- Optimised Filtration Performance

The systems are designed for continuous operation and can handle varying fume levels. They can adapt to any operating specificities such as huge variations in terms of flow rate or temperature.